Rapid prototyping is a revolutionary concept that has been changing the game for product designers, manufacturers, and software developers alike. The advantages of rapid prototyping are numerous, and this transformative approach is the driving force behind many success stories. Stick around and see how it can have a positive impact on your projects as well.

What Is Rapid Prototyping and What Are Its Benefits?

Rapid prototyping creates physical prototypes, redefining how ideas come to life swiftly and cost-effectively. Exploring the benefits of rapid prototyping is essential for elevating your projects. In a market with 30,000 new products annually, distinguishing your brand is crucial. Incorporating prototyping in the early production stages is highly effective, as it helps verify concepts, assess designs, and secure approvals.

This transformative approach offers six pivotal advantages that can revolutionize your projects. It accelerates development, trims costs, enhances product quality, allows for customization, and significantly reduces risks. By harnessing these benefits, you can propel your ideas to fruition faster, more efficiently, and with a higher probability of success.

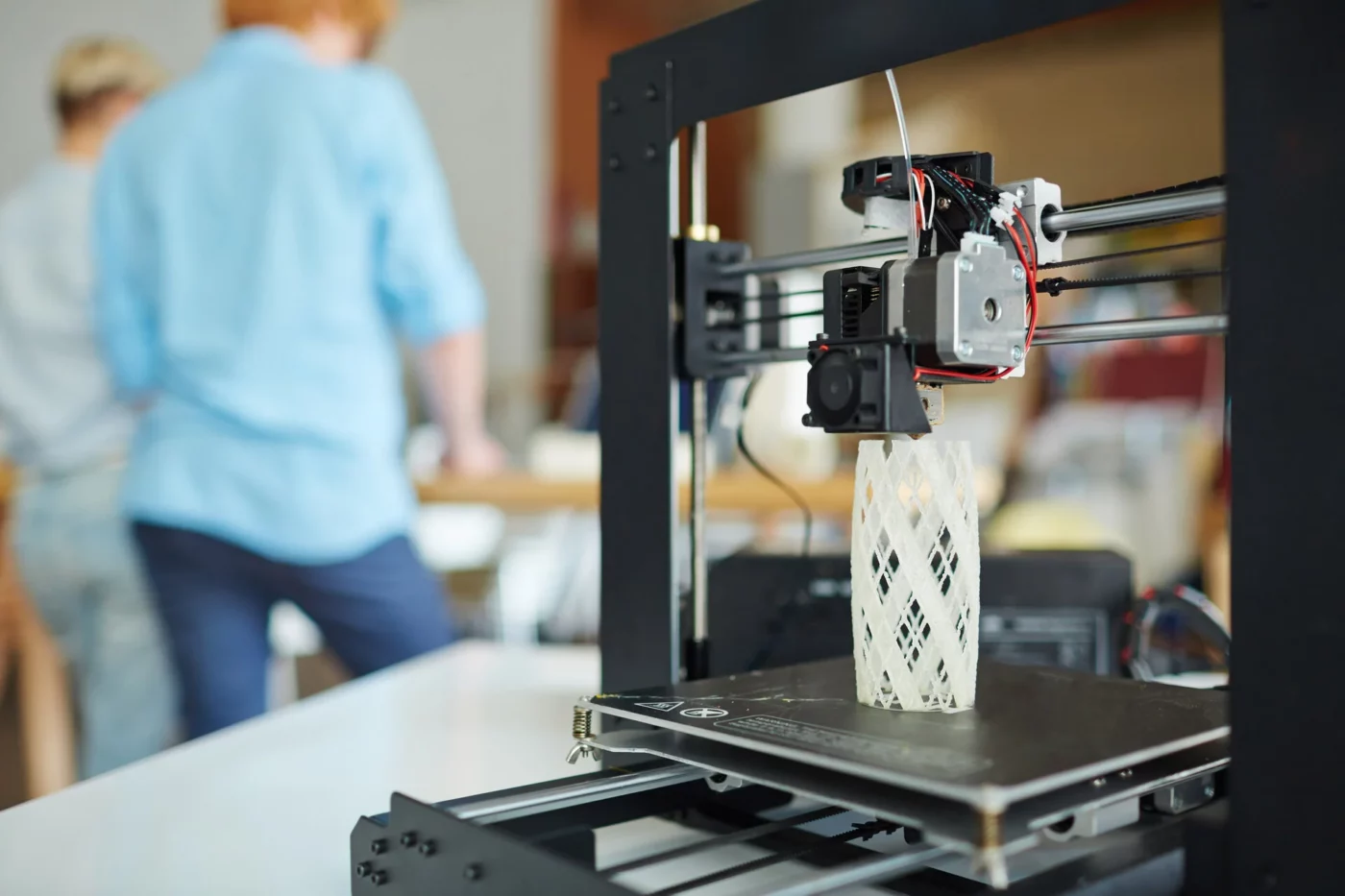

#1 Advantage – Faster Development With 3D Printing and CAD

Traditional product development can be time-consuming, often taking months or even years to move from the initial idea to a tangible prototype. However, with rapid prototyping development, this timeline is drastically compressed.

This rapid progress is made possible through modern technologies like 3D printing and computer-aided design (CAD). Rather than manual prototype construction or costly molds, rapid prototyping swiftly produces precise, detailed models using digital design and rapid manufacturing. This approach supports quick iterations, on-the-fly improvements, and instant evaluation of design changes’ impact on the final product.

Tesla’s Revolutionizing Automotive Development

Tesla is reportedly employing a new, confidential method that merges 3D printing and industrial sand, as per information from five sources well-versed in the undisclosed process. In this approach, a mold features 3D-printed solid sand cores, which are subsequently removed after casting, resulting in a hollow subframe designed to enhance structural integrity. This innovative technique provides Tesla with greater flexibility for adjustments concerning cost, design, and timing when compared to traditional metal molds.

#2 Advantage – Cost Savings Over Traditional Prototyping Methods

Cost efficiency is a hallmark of rapid prototyping, making it a strategic choice for businesses looking to minimize expenses while maximizing innovation. One of the primary ways it achieves this is by significantly reducing the risk of costly errors.

In traditional product development, mistakes made late in the design or manufacturing process can be prohibitively expensive to rectify. Rapid prototyping allows for early and frequent testing, catching potential issues before they become expensive problems. This proactive approach not only saves time but also prevents costly overhauls down the line.

The Advantage of Selective Laser Sintering (SLS) and Other Techniques for Making Final-Use Components

Specific 3D printing techniques like direct metal laser sintering (DMLS), selective laser sintering (SLS), HP Multi Jet Fusion (HP MJF), and Carbon DLSTM are well-suited for creating final-use components. Consequently, the consolidation of parts during both the prototyping and production phases can lead to substantial cost reductions throughout the product development process.

#3 Advantage – Enhanced Product Quality and Test Opportunities

Rapid prototyping is not just about speed – it’s equally about the pursuit of perfection. The most compelling advantage is its ability to refine and elevate the quality of products. Through the iterative testing and feedback loops made possible by rapid prototyping, designers and engineers can identify and rectify issues at an early stage. This approach ensures that the final product is not only developed faster but also of higher quality, meeting or even exceeding the desired standards.

Consider the Disadvantages of Limitations of Material Compatibility in Rapid Prototyping

3D printers are unable to produce objects made of wood, cloth, paper, or rock, making rapid prototyping unsuitable for creating prototypes that necessitate these materials. Rapid prototyping is best suited for metal and plastic parts manufacturing and the replication of other material forms. For instance, when a wooden sculpture is needed, it can be printed in plastic to generate a true-to-scale prototype for artistic reference.

#4 Advantage – Flexibility and Customization for Hardware and Software Prototyping

Adaptability is a prized asset, and rapid prototyping excels in this aspect. It offers unparalleled flexibility in design and production, allowing designers to explore a spectrum of ideas without being constrained by traditional manufacturing limitations. This agility extends to customization as well, enabling the tailoring of prototypes to specific needs, whether it’s for individual consumers or niche markets.

Custom-Fit Footwear Was Nike’s Rapid Prototyping Triumph

A prime example of the power of flexibility and customization can be seen in the footwear industry. Companies like Nike utilize rapid prototyping to offer custom-fit sneakers designed to match the precise contours of an athlete’s foot.

They’ve not only catered to a diverse customer base but also gained a competitive edge in a crowded market. Rapid prototyping’s ability to adapt and customize is a testament to its potential to meet the demands of today’s discerning consumers and drive project success through innovation and personalization.

#5 Advantage – Risk Reduction With Clear Project’s Weakness and Strength

Risks are ever-present, and mitigating them is essential for success. Rapid hardware prototyping emerges as a powerful ally in this endeavor, as it plays a crucial role in identifying and addressing issues at an early stage.

With a tangible model for assessment and testing, it offers a crystal-clear picture of a project’s strengths and weaknesses, allowing designers and engineers to make informed decisions and strategic adjustments.

Experience the Advantages of Rapid Prototyping Services With Juratech Solutions

The realm of software development is multifaceted, encompassing both the backend and frontend aspects. It speeds up development, reduces costs, enhances collaboration, improves product quality, and allows for customization while mitigating risks. The same works for hardware development, as well. This innovative approach is a force to be reckoned with across various industries.

As you reflect on both the advantages and disadvantages of rapid prototyping, consider what we at Juratech do and how we can drive your projects forward, whether you’re focusing on backend web development or frontend web development services. Don’t miss the chance to explore its game-changing potential. For expert guidance and solutions, reach out to Juratech Solutions today and unlock a world of possibilities for your ventures.